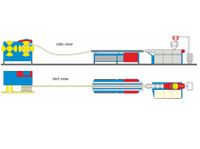

The profilline c-series is designed for a highly flexible production. The machinery will produce different sizes of core tubes, tailor made for the p-series extrusion line:

Core OD 31,0 mm

Core OD 53,2 mm

Core OD 84,3 mm

Core OD 110,0 mm

The machinery is equipped with a double coil station in order to allow a continuous production. The coils are put on stock as a buffer and are used later at the p-series just in time.

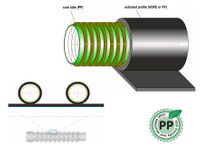

Core tube as precursor for the p-series

The profilline p-series needs a core tube as precursor for the profile production (besides the resin, PE or PP). The customer has the choice to buy such a core tube from his local market (it is normally available for the electric installation in houses) or to get a profilline c-series to manufacture the core tube by himself.

The core tube needs a good flexibility combined with a high ring stiffness, but most of all it needs a high thermal stability. The tube is covered in the die head of the p-series later with 200°C hot PE or PP and it has to keep its round form until the surrounding hot material cools down.

The necessary temperature resistance is guaranteed by a special profile design of the core tube and the modern PP which we use as a resin for the c-series machine.

diameter range OD 31,0 to OD 110,0 mm

pipe length up to 750 m

stiffness values SN 12 to SN 160

output capacity up to 180 kg/h

resin: modern PP